7.10 Terminal Stair Tower Ramp Access

7.10.1 General Design Considerations for Terminal Stair Tower Ramp Access

A. Reference Standards: Comply with Volume 3, Appendix 3B - Codes and Standards. Particular attention should be given to COMAR 05.02.02 Maryland State Accessibility Code, Americans with Disabilities Act Accessibility Standards, International Building Code, and NFPA 101 Life Safety Code.

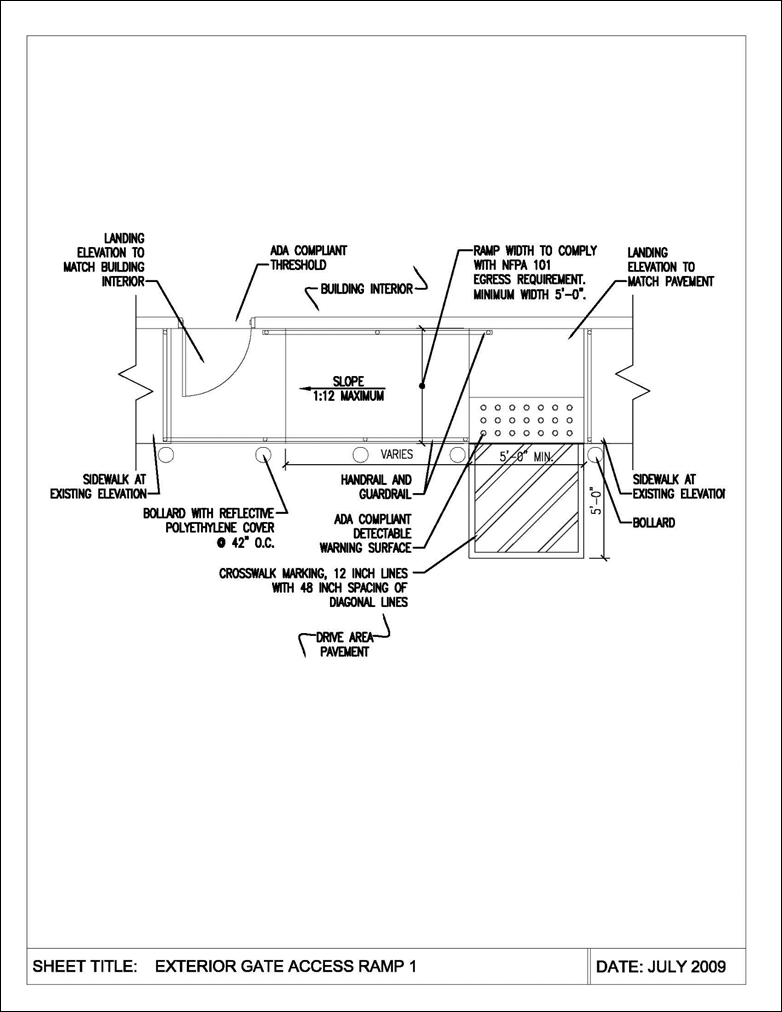

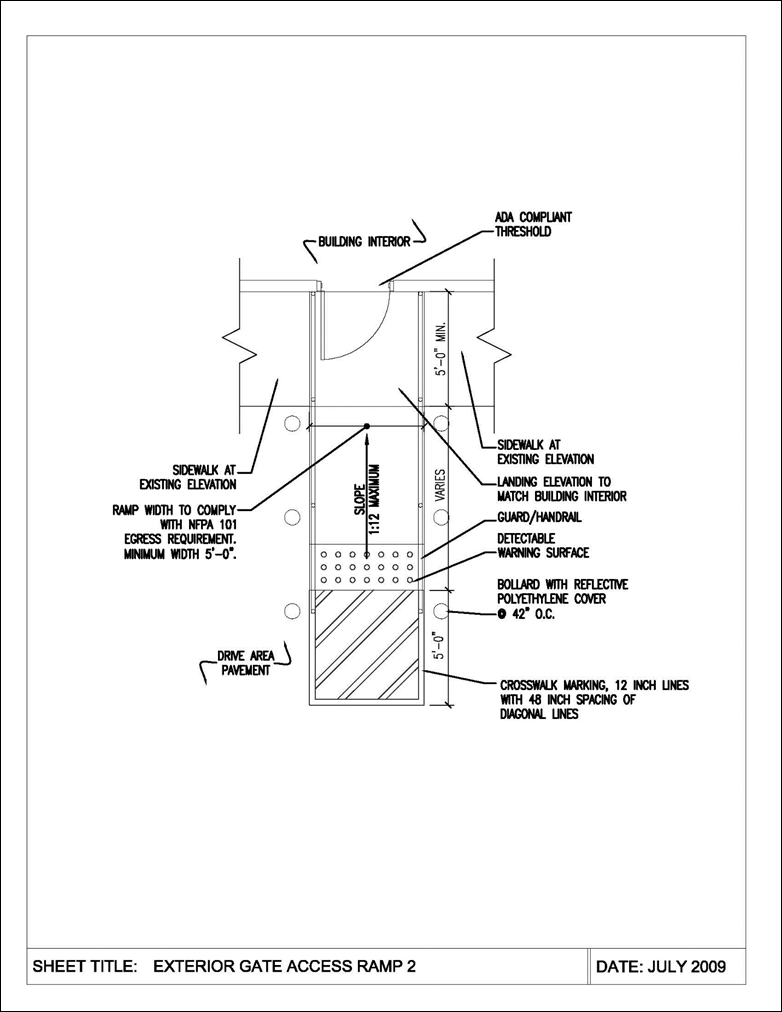

B. Hand/Guardrails: All BWI Marshall exterior gate ramps will have handrails and guard railings as shown on the following exhibits. These rails will meet or exceed the code requirements. The rails are intended to direct pedestrians to the ramp and entry door.

C. Door Landing: The exterior landing will be at the same elevation as the interior of the building. Provide a guardrail on each side of the landing to indicate the elevation difference between the landing and the adjacent sidewalk.

D. Doors: Provide new door, frame, and hardware as required to comply with ADAAG standards and changed exterior building conditions modified to comply with this standard.

E. Threshold: Provide ADAAG compliant extruded aluminum thresholds with integral weather seal.

F. Bollards: Provide as required to protect the ramp from vehicular traffic in accordance with Section 6.5.2 Bollards.

G. Pavement Walkways: Provide a walkway path, delineated by pavement paint, extending 5’-0” toward the aircraft parking area from the end of the access ramp.

7.10.2 Ramp Configuration

Each location identified for a new ramp should be studied during the initial design process to ensure the location does not impact:

A. Vehicular traffic and parking spaces

B. Apron vehicle traffic and parking

C. Aircraft traffic and parking

D. Ground Service Equipment (GSE) locations

The configuration and geometry of ramps may vary depending on physical constraints surrounding the exterior doors. It is expected that most ramps can be configured in a manner similar to the following exhibits. The actual configuration of doors and curbs will vary around the perimeter of the concourses. It is the design professional’s responsibility to modify the designs to suit each field condition while maintaining the intent of the standard.

Design ramps in accordance with the following Exhibits. The first exhibit is applicable where the ramp will be located parallel with the building and integrated into the existing sidewalk. The second exhibit is applicable where the ramp will be located perpendicular to the building.

7.10.3 Ramp Construction Requirements

A. Ramp Pavement:

1. Concrete: 3000 psi @ 28 days, complying with ACI 301.

2. Finish: Light Broom.

3. Detectable Warning Surface: ADAAG compliant 1-3/8 inch thick precast concrete core, reinforced epoxy tiles.

B. Pavement Markings: Provide pavement paint to comply with Chapter 6.4 Pavement Markings.

C. Handrails and Guardrails:

1. Galvanized steel pipe or tube. 1-½ inch outside diameter.

2. Capable of withstanding following; concentrated load of 890 N (200 pounds) applied at any point in any direction and uniform load of 730 N/m (50 PLF) applied in any direction. Concentrated and uniform loads above need not be applied simultaneously.

3. Paint: In accordance with MPI EXT 5.3B, Alkyd System.

D. Vehicular Traffic Protection: Bollards in accordance with Section 6.5.2 Bollards.

E. Doors, Frames, and Hardware:

1. Doors and frames: Provide galvanized seamless hollow metal doors with welded frames. Comply with SDI-100, Level 3, Model 2.

2. Hinges: Stainless steel ball bearing type.

3. Locksets: Lever type complying with ADAAG standards. Provide lever that returns to door face to avoid possibility of catching fire hoses in an emergency situation.

4. Cores: Provide in accordance with MDOT MAA PEGS Manual Appendix 2D - Standard Specifications.

F. Lighting:

1. Purpose: Provide pedestrian lighting for ramps.

2. Lighting Level: Minimum of 5 footcandles with an average uniformity of 3 to 1of lighting on the ramp.

3. Comply with Chapter 12 Lighting.

4. Light Fixture: Wall pack type fixture, 250w/120v with metal halide lamp with top visor and side shields. UL/CUL Listed for wet locations at 40C. UL Listed Marine Outdoor. Class I, Division 2 Class II, Div 1 & 2 Class III, Div 1 & 2. Provide Holophane Predator or similar.