15.4 Typical Passenger Boarding Bridge Accessories

The following accessories are typically included and installed on a PBB and shall be discussed and confirmed with the Task Manager during the design effort and specified by the design consultant. As the MDOT MAA owns the PBB, they do not typically provide for or own the preconditioned air units or 400 Hz systems at domestic gates. Consultant is to confirm whether these items are to be provided.

15.4.1 Pantograph or Cable Conveyance System

Any new or relocated PBB shall be provided with a cable conveyance system of sufficient capacity to accommodate PC Air and 400 Hz units for the design aircraft fleet mix at the gate for which the PBB is intended. At a minimum, one four-inch (4”) diameter aluminum pantograph will be provided, with length to cover the movable sections of the PBB for routing power to the PC Air and 400 Hz units. (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications).

15.4.2 Telephone

The PBB manufacturer shall make provisions for telephone service. There shall be one telephone outlet integrated in the cab area of the PBB. As a result, the design consultant shall coordinate with MDOT MAA’s Office of Information Technology and shall provide adequate information in the plans and specifications to ensure that telephone service is provided at the PBB (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications).

15.4.3 Pre-Conditioned Air

The MDOT MAA does not typically provide Pre-Conditioned Air (PCA) units at domestic gates as previously noted. PCA units are typically owned by the airlines. If a PBB with a PCA unit is being relocated, the airline who owns the gate is to remove and reinstall on the PBB placed at the gate. This includes new or relocated PBBs.

PCA units installed on PBBs require structural and electrical load calculations to ensure the electrical loads can be supported by both the PBB and the electrical infrastructure. As a result, the design consultants shall provide adequate information in the plans and specifications to ensure that the load requirements, the power requirements, and contractual arrangements are satisfied. For additional requirements including utility metering installation requirements, refer to Section 15.5 Pre-Conditioned Air and 400 Hertz Systems and Associated Loading Bridge Requirements Chapter 11.1.2 Total Harmonic Distortion (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications). The Consultant shall locate the units based on the combined geometry of the PBB and aircraft layout to ensure that there are no conflicts with the equipment placement.

15.4.4 400 Hertz Point-of-Use

The MDOT MAA does not typically provide 400 Hertz (Hz) units at domestic gates as previously noted. 400 Hz units are typically owned by the airlines. If a PBB with a 400 Hz unit is being relocated, the airline who owns the gate is to remove and reinstall on the PBB placed at the gate. This includes new or relocated PBBs.

400 Hz Point-of-Use (POU) units installed on PBB(s) require structural and electrical load calculations to ensure the loads can be supported by both the PBB and the electrical infrastructure. As a result, the design consultant shall provide adequate information in the plans and specifications to ensure that the load requirements, the power requirements, and contractual arrangements are satisfied. For additional requirements including utility metering installation requirements, refer to Chapter 15.5 Pre-Conditioned Air and 400 Hertz Systems, Associated Loading Bridge Requirements, and Chapter 11.1.2 Total Harmonic Distortion (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications). The Consultant shall locate the units based on the combined geometry of the PBB and aircraft layout, and capability to accommodate regional jets to ensure that there are no conflicts with the equipment placement.

15.4.5 Electrical Submetering

Refer to Section 15.5.2 Metering.

15.4.6 Adjustable Cab Floor (Articulating Cab Floor (ACF))

All BWI Marshall PBBs shall be Regional Jet (RJ) capable. PBBs to be utilized for mating to regional jets shall be equipped with an adjustable cab floor to allow proper mating to the regional jet aircraft while preserving the ability of the PBB to be utilized for wider bodied aircraft. RJ capable bridges include the following:

A. Floor flap adjustment for RJ doors.

B. Fold out hand rails necessary for extension into the RJs with retractable air stairs.

C. Additional cushion on PBB for contact mating of bridge and aircraft fuselage.

The consultant shall provide the minimum and maximum height ranges required to be serviced at each individual gate by the PBB. The consultant shall identify to the MDOT MAA Project Manager and identify in the design report any restriction to larger aircraft using the PBB as a result of the RJ usage.

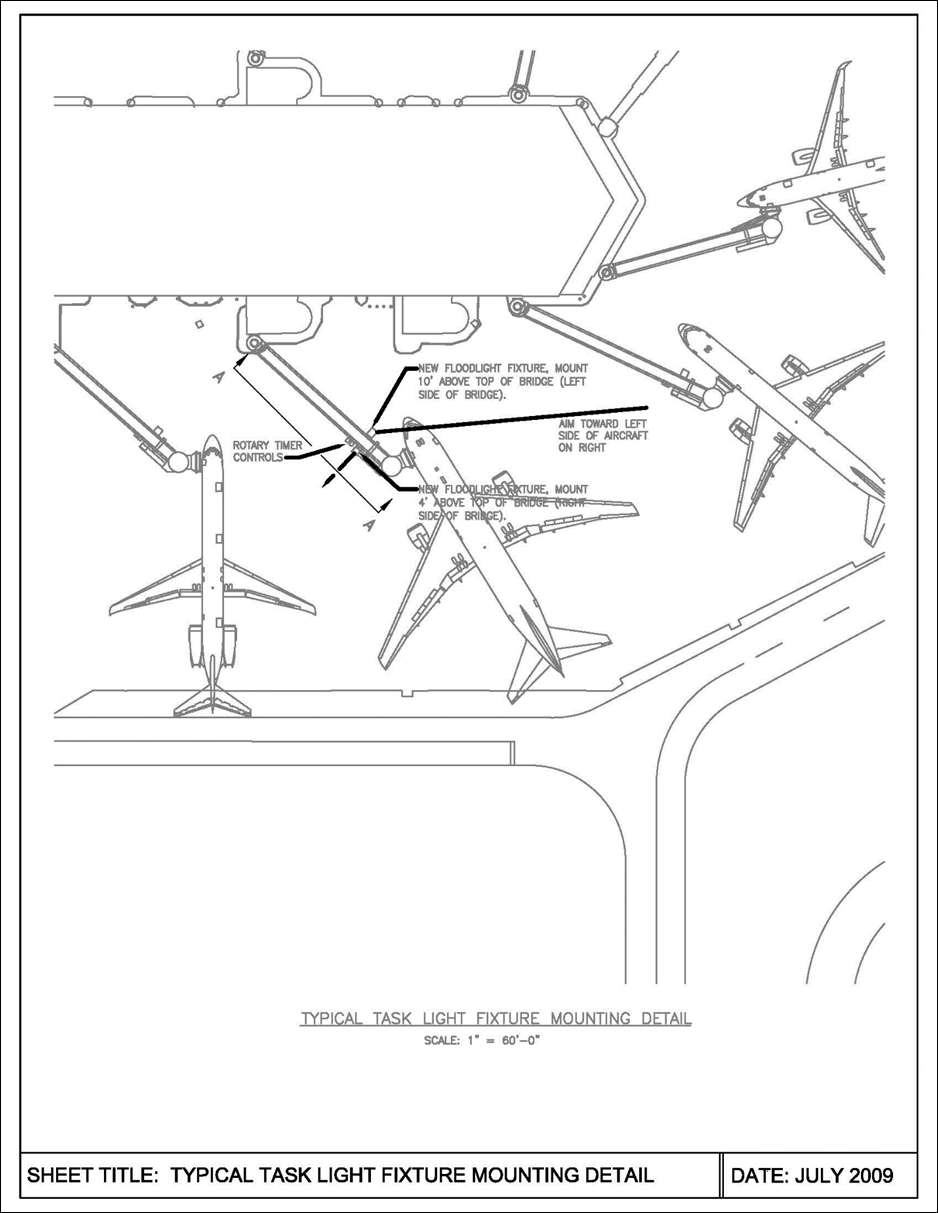

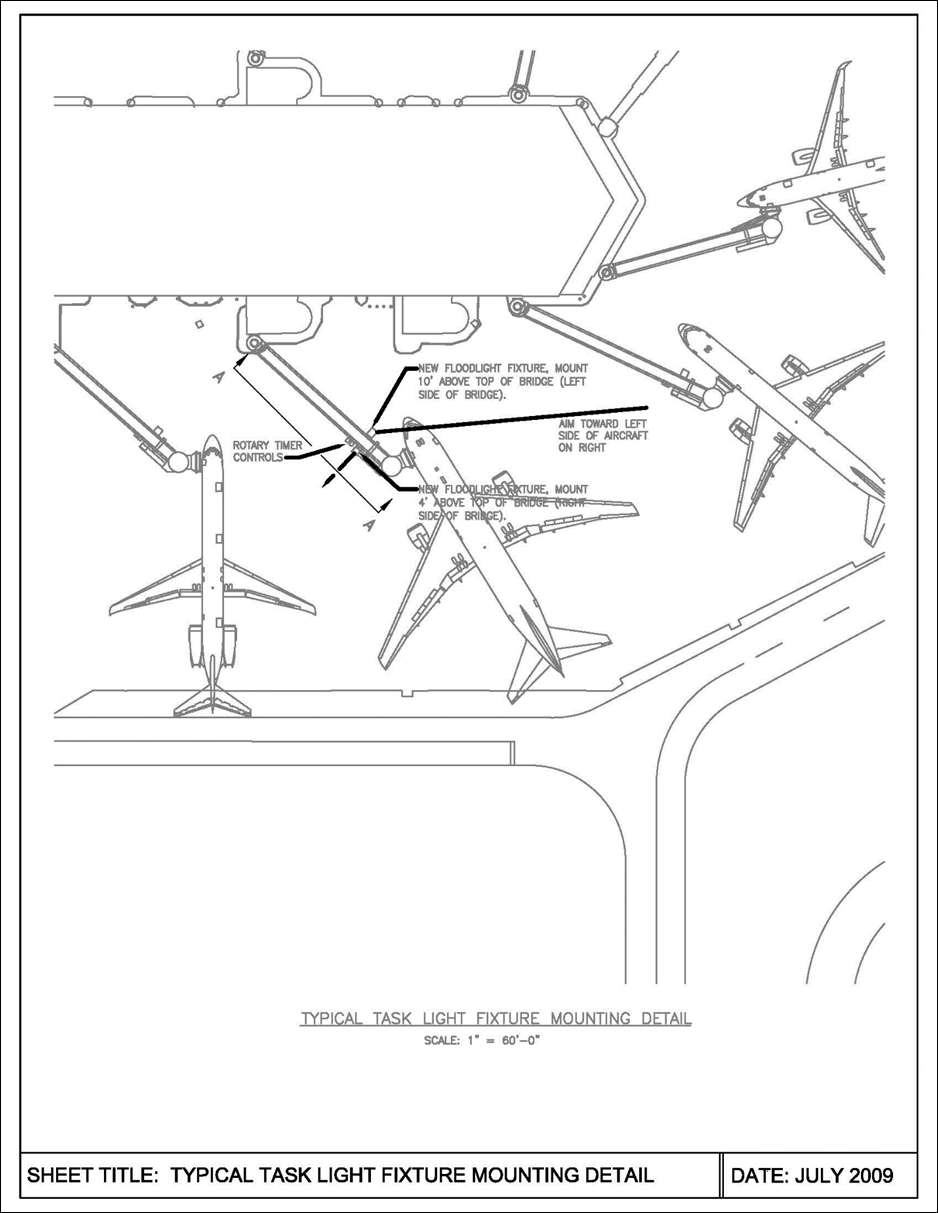

15.4.7 Task Lighting

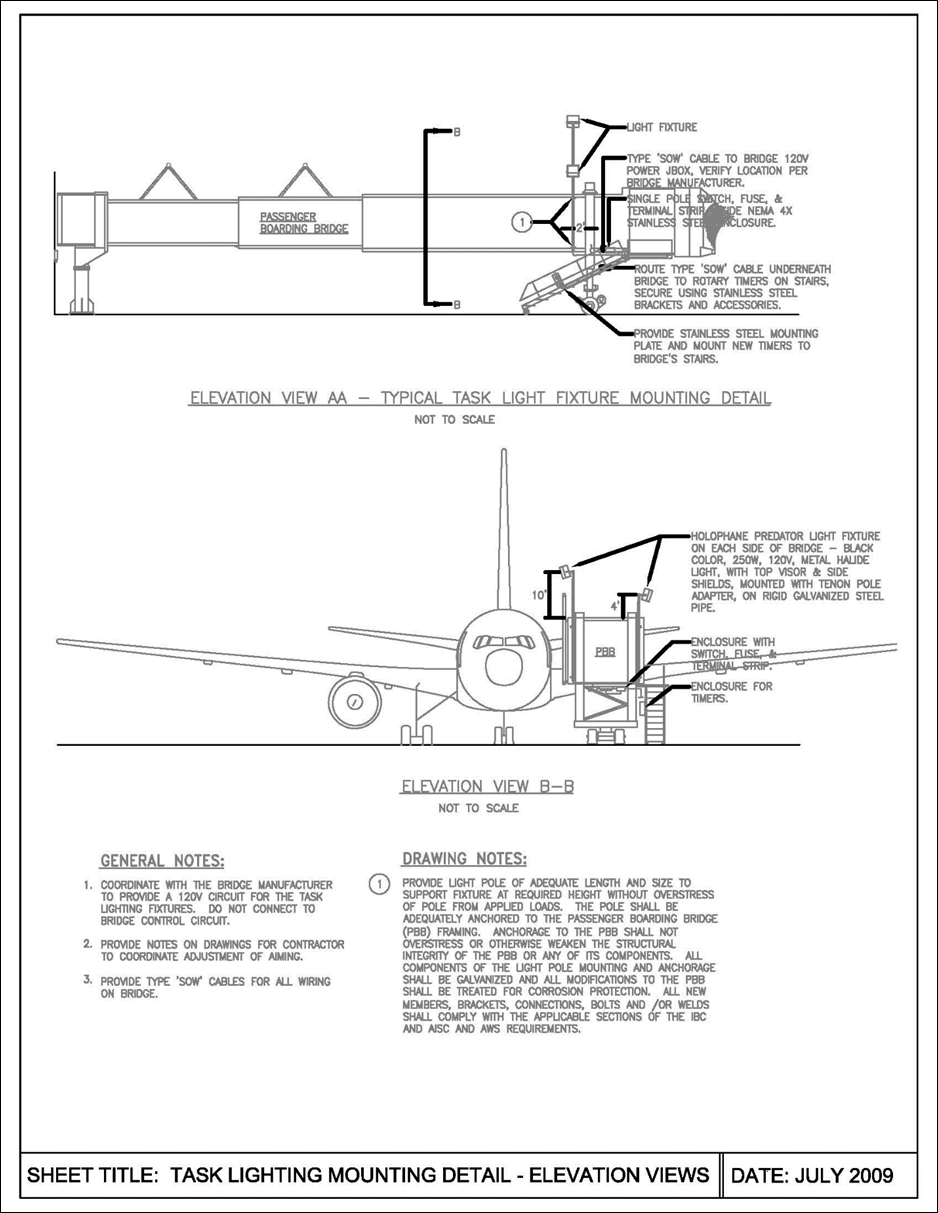

Task Lighting installed on PBBs shall consist of two (2) floodlight fixtures. The first floodlight fixture shall be mounted 4 feet above the top of the PBB on the right side of the PBB to illuminate the apron area in the swept path of the PBB. The second floodlight fixture shall be mounted 10 feet above the left side of the PBB on the left side of the PBB to illuminate the apron area adjacent to the aircraft (See Typical Task Light Fixture Mounting Detail).

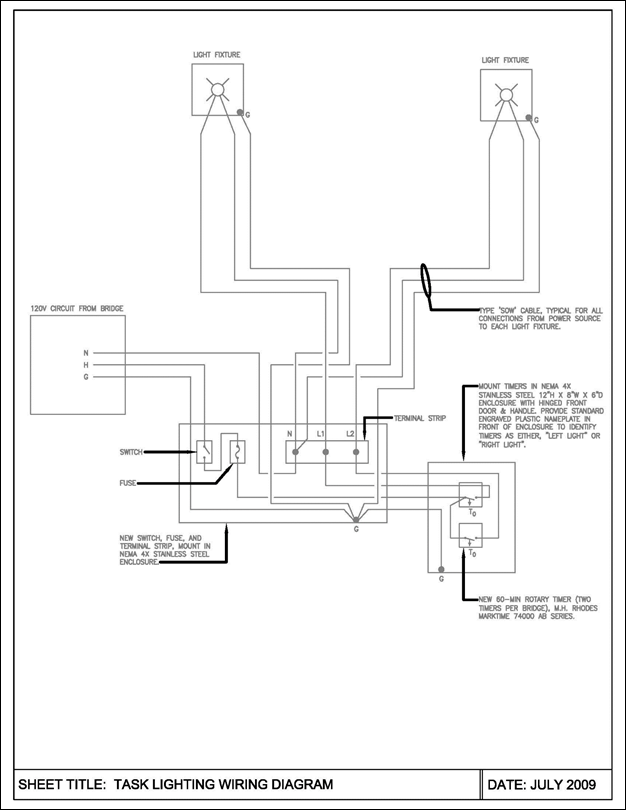

The floodlight fixtures require structural and electrical load calculations to ensure the added structural and electrical loads can be supported by both the PBB and the electrical infrastructure (See Task Lighting Mounting Detail - Elevation on the following pages). All calculations shall be signed and sealed by a professional engineer for the respective design responsibility and included in a design report. Task Lighting installations shall contain two (2) LED 60-minute rotary timers to minimize lighting costs (See Task Lighting Wiring Diagram on the following pages) (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications).

15.4.8 Solid Tires

Solid Rubber Tires shall be included in the specification requirements for all BWI Marshall PBBs.

15.4.9 Gate Identification Signs

Three Sided Gate Identification Signs shall be installed on new or relocated PBBs (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications).

15.4.10 Baggage Slides

Automated baggage slides are not to be provided with new (or relocated) bridges. The consultant shall coordinate with MDOT MAA Commercial Management to confirm. The consultant shall also coordinate with Commercial Management to confirm current accessories located at each gate (i.e. - cover, motorized lifting platform, etc.) and airline preferences, if any.

15.4.11 Subflooring

Subflooring on new PBB’s shall be galvanized/galvanealed smooth steel or three quarter inch (3/4”) marine grade plywood.

15.4.12 Finished Flooring

Cab flooring shall be of ribbed rubber (see Specification 347713X Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications for additional detail). Carpet shall be installed on the flooring of the PBBs (See Specification 347713X Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications). Per NFPA 415, carpet shall meet the requirements for Class-I carpet flame spread rating.

Consultants shall specify an additional 10% of carpet quantity in each contract to be used as MROI (a.k.a. attic stock). The amount shall be confirmed with MDOT MAA Office of Facilities Maintenance. (Refer to DST Chapter 4.5 Maintenance Repair and Operating Items MROI).

15.4.13 Exterior Finishes

Surface preparation, primer, and finish coat for the PBBs shall be provided (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications).

15.4.14 Canopy

In order to satisfy NFPA 415, the PBB canopy is required to be lowered to mate with the aircraft fuselage. To ensure the PBB operator lowers to the canopy, the PBB manufacture shall include the lowering of the canopy in the sequence of operation, or program an alarm to sound as a reminder. (See Specification 347713X_Apron Drive Passenger Boarding Bridges in Appendix 2D - Standard Specifications).

15.4.15 Occupancy Sensors

Occupancy Sensors shall be installed on new or relocated PBBs to automatically turn off the interior lights and exhaust fans when the PBB is not in use.

15.4.16 Relocated Bridge

If a bridge is to be relocated from one (1) location to another, the bridge shall be reviewed for code compliance and refurbished to meet current codes.